|

High density Interconnection (HDI)

Introduction

High Density Interconnects (HDI) board are defined as a board (PCB) with a higher wiring density per unit area than conventional printed circuit boards (PCB). They have finer lines and spaces (<100 µm), smaller vias (<150 µm) and capture pads (<400 µm), I/O>300, and higher connection pad density (>20 pads/cm2) than employed in conventional PCB technology. HDI board is used to reduce size and weight, as well as to enhance electrical performance.

Main Application

mobile phone、PDA、V8、Digital Camera

Specification

| Capability |

UNIT |

STANDARD |

SPECIAL |

| Layer Count |

Layers |

6-8 |

Max. 32 |

| Total Thickness (Min/Max) |

mm |

0.8/1.6 |

0.4/3.2 |

| Min. Line/Space |

μm |

150/150 |

120/120 |

| Min. Via/Land |

μm |

300/600 |

250/500 |

| Base Material |

|

CEM3, FR-4, FR-5(High-Tg), H-Free |

| Surface Treatment |

|

HSAL/OSP/Immersion Gold |

Tin/Silver |

Layer Structure

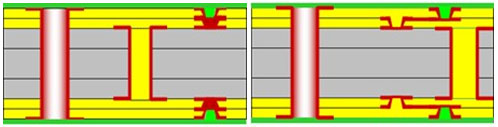

• HDI PCB (1+N+1)

• HDI PCB (2+N+2)

• ELIC (Every Layer Interconnection)

|